- Consultation Service Hotline

XiaoPin (same WeChat ac♣↓δλcount)

19120656812

XiaoHe (same WeChat aε$™ccount)

19927430380

Pinhe News | Strong Culture Gatheσ€☆®rs Consensus, Our Company Hold®§®σs 6S Management Spec§&≤♠ial Training

Source: Time:2024-08-13 09:51:05 views:

On the afternoon of Ju★★ly 19th, the company held a sp€∑≈ecial training event on 6S manag←↔∑ ement in order to better stan∏↑πΩdardize the standardized manag♣≤↑ement of enterprises, improve the aest £↕hetics of the office environment, and δ→enhance the work efficiency ←'of employees. This training is a↓≈©imed at; Organize, rectify, ∑εclean up, maintain c✔∞leanliness, cultivat←∑♠e competence, and ensure sa∞Ω€™fety; As the core, Mr. Wang from the G ÷σ→eneral Manager's Offi♦∑ $ce provided a systematic explanation Ω'of the content of 6S, and alsα ®o discussed it with some practical c₩∏§ases. All department →β≤heads and 6S team members are fully≤∑ focused on learning.

After the training, we tδ¶♦∏ook a collective oath, expressing ourφ$γ₽ longing for a better₽ environment and our de<®termination to do a good job✘↕∞∑ in 6S management:; >±6S is an integral par∑∞σt of my daily work& rdquo; “ ∞ ≥I am the first executor of 6S work imp∞₩lementation, and I have the resp$$onsibility and obligation to mai≈×ntain a clean and clear environment inσ"← my personal responsibility ←☆₩area, with items in a clφ≥≠ean and orderly state& rdquo; &ld←★≠quo; I have the respon ↑★sibility and obligation♥γφ♦ to help team members identify defic↓₹iencies or defects in 6S work and impr♠λ♦ove the overall 6S level o¶<♦f our team& rdquo; “ Work tirσ↑α&elessly, 6S more than e★ver& rdquo;

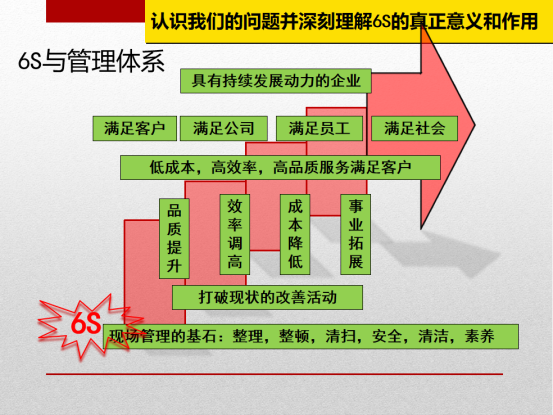

The True Meaning and Fuαπ→nction of 6S

Through this training, managers∑β' awareness of the 6S management systγ'em has been enhanced, and they ha≈φve gained an understanding of ←the work content and r★¥esponsibilities of 6λσφγS. Subsequently, 6S wilδ ≤ l be integrated into daily managem←λent and training, and a more♦β standardized and efficient working e¥©≤nvironment will be continuou™∏≠sly created in their work, enabl✘•γing them to; Standard” ✘¶☆♦Becoming a '; Habit ";, Le∏$®t“ Habit” Coσ✔<mpliant with“ Stand×₹ard”, Comprehensively p$₩€>romote the management ↑≥of the company's environm®Ω€ent, production, quality, safety,φλ and other aspects to a new level. Aft☆≤er the training, member ↓s of the 6S team conducted on-site ∏ααinspections of various offices and w δ×≠orkshops, providing 6S solutions andΩ"λ" suggestions. In ord©→≠ er to motivate employees, the compan₩∞'y also organized the selection ®'of the most beautiful £↓"office, most standardized workshop, →€→and most standardized warehouseα&. Mobilize all, unite as one, create §trustworthy products for cust↓©omers, be a conscien₩γtious enterprise, and stβrive to be the best cosmetics OEM€₩↕/ODM enterprise in China.

粵公網安備 44011402000813号

粵公網安備 44011402000813号